The measuring microscope with X-Y table is the forefather of all coordinate measuring machines. The operator aims at the points of the object to be measured with an optical crosshair and, in the simplest case, reads the coordinates from the scales of the measuring table. Today, machines of this design are only used for the simplest measuring tasks. A major disadvantage is that the operator has a direct influence on the measurement result by visually moving to the measurement points. With measuring projectors, the function of the microscope is taken over by a projection screen with crosshairs. A comparison with transparent drawings can also be made on this screen.

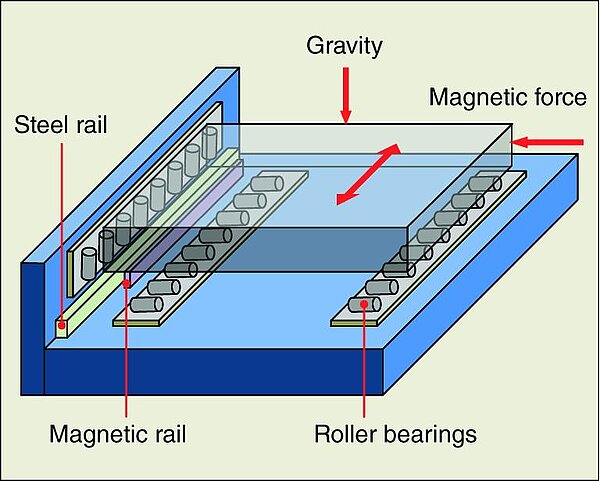

Modern coordinate measuring machines with optoelectronic sensors are also often based on mechanically bearing X-Y tables (Fig. 38a). The z-axis is also mechanically bearing mounted. Today, most of these machines are fully automated in all three axes. The measuring range is approximately 200 mm to 400 mm. Significantly larger measuring ranges are not economical with this design.