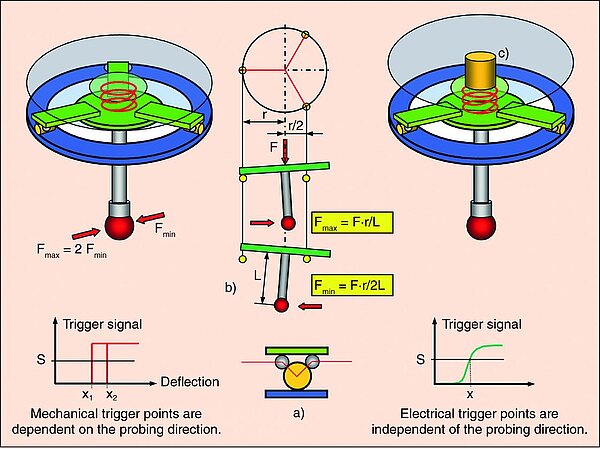

Simple touch trigger probes work according to the tripod principle (Fig. 27 left). When the stylus tip contacts the measuring object, a signal (trigger) is generated to read out the scale systems of the coordinate measuring machine. The measurement points are derived from the coordinates of the measuring machine and refer to the centre of the stylus tip. This is mounted via a rigid shaft on a three-point bearing, which is designed as a switch in each of the three supports. If the stylus is deflected from any orientation, at least one switch is opened. This is further processed as a trigger signal. The main disadvantage of this system is that the probing forces are highly dependent on the probing direction. This leads to different probe deflection and thus to a non-negligible direction-dependent probing error (triangular characteristic), which is difficult to correct.

- Development

-

Machines

- Coordinate measuring machines with X-Y table

- Coordinate measuring machines with guideways in a single plane

- Coordinate measuring machines with bridge

- Coordinate measuring machines with rotary axes

- Coordinate measuring machines for two-dimensional measurements

- Coordinate measuring machines with X-ray tomography

- Coordinate measuring machines for special applications

- Sensors

- Software

- Special characteristics

- Accuracy

- Publications

- Literature page